Risk Assessment Managenent

Compliance and risk management in commercial office spaces involve identifying, assessing, and mitigating potential risks, ensuring adherence to regulatory standards. Regular audits, inspections, documentation, and proactive management protect occupants, maintain operational continuity, enhance safety, and reduce liabilities effectively

Water (Legionella)

Compliance regarding water and Legionella control in commercial offices involves risk assessments, regular monitoring, testing, and preventative maintenance in accordance with L8 regulations. Proper documentation and management procedures ensure water safety, protecting occupants from health risks and ensuring regulatory adherence.

Fire (escape, doors, compartmentation)

Fire compliance in commercial offices involves regular inspection and maintenance of escape routes, fire doors, and compartmentation. Ensuring clear, accessible exits, functional fire doors, and effective compartment barriers helps prevent fire spread, protects occupants, maintains safety standards, and meets regulatory obligations.

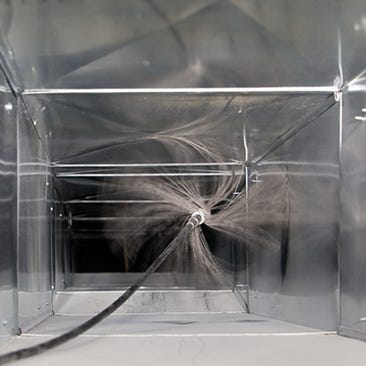

Ductwork Hygiene

Compliance with ductwork hygiene in commercial offices involves routine inspections, cleaning, and maintenance according to TR19 standards. Regular audits, testing, and documentation ensure duct cleanliness, prevent fire risks, enhance indoor air quality, maintain system efficiency, and meet regulatory requirements.

© Property Solutions Management Group Ltd